i4SERV Projects

Delivering cutting-edge Industrial Automation, HVAC, and IoT Solutions tailored to your operational needs.

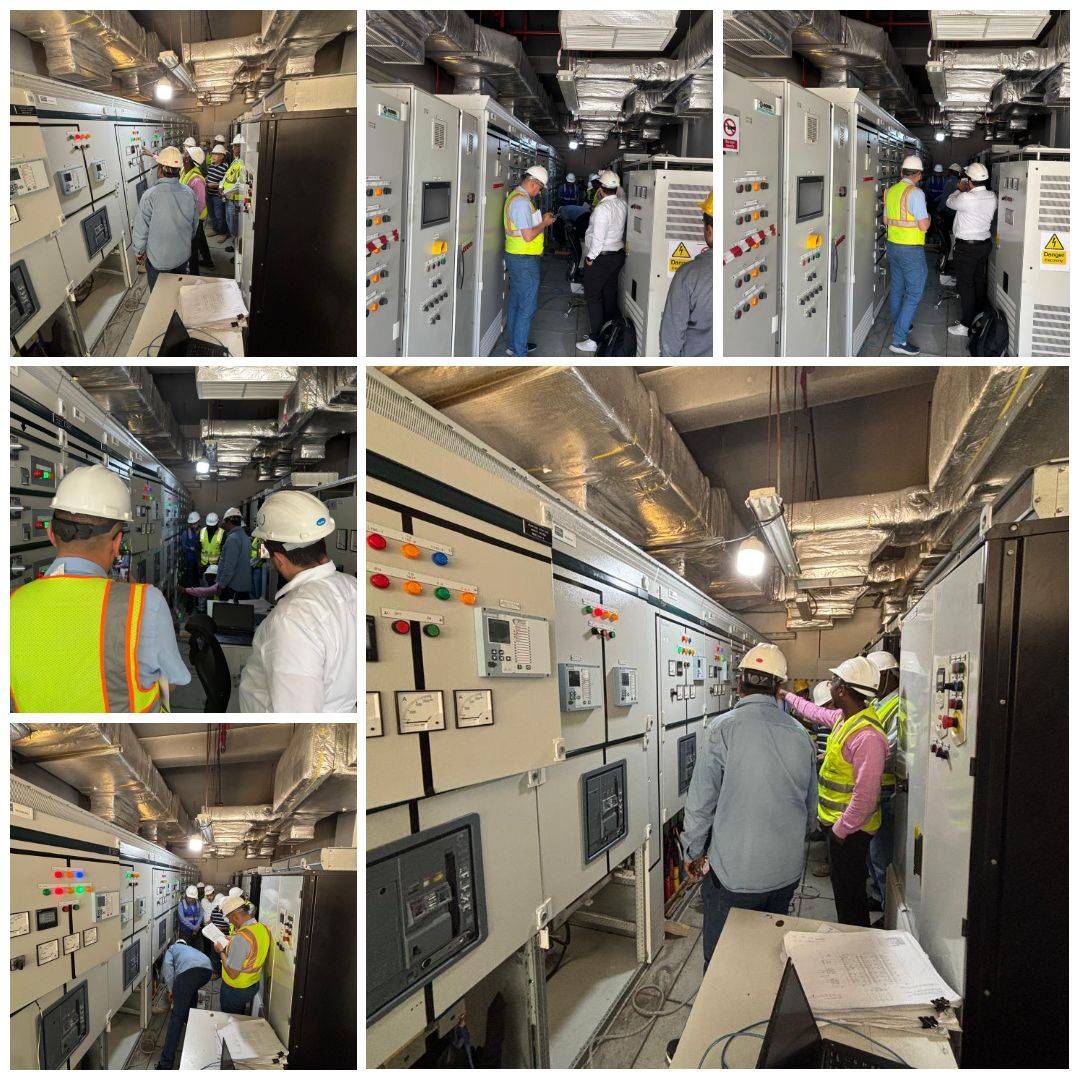

Commissioning of Protection Relays, LV Switch Gear System & Siemens PLC

Project Overview

I4Serv successfully programmed and commissioned Protection Relays, LV Switch Gear System, and Siemens PLC for a major industrial client. The project involved seamless configuration of critical control elements, ensuring reliable performance of low voltage electrical infrastructure.

Key Deliveries

- Complete programming and integration of Siemens PLC

- Configuration of LV Switch Gears and Protection Relays

- Auto Operation Testing across multiple failure and performance scenarios

- Collaboration with client’s operation team for commissioning validation

Impact

This deployment significantly enhanced the reliability, operational safety, and automation efficiency of the plant’s electrical systems — laying the groundwork for uninterrupted production.

Watch the full project video here

Watch the full project video here

Upgrading Crates Tracks Automation System & MCC Panels for a Leading Food Brand

Project Overview

I4Serv proudly announces the successful upgrade of the Crates Tracks Automation System and MCC panels for a premium food sector brand in Al Kharj. The project stands as a testament to I4Serv’s engineering precision and phase-wise execution to ensure minimal disruption to ongoing operations.

Key Deliveries

- MCC panel design with 50 SINAMICS VFDs

- Integration of Main PLC S7-1500, distributed RIOs, and WinCC Unified HMIs

- Software & HMI development

- Phase-wise deployment across four crate tracks

- Full engineering, programming, and delivery managed by I4Serv's expert team

Impact

The phased upgrade provided uninterrupted functionality while modernizing the plant’s automation capabilities, ensuring scalability, reliability, and enhanced system control.

Watch the full project video here

Watch the full project video here

Agitator Control and Siemens Programming for Chemical Process Plant

Project Overview

I4Serv is proud to contribute to a Chemical Process Plant by managing critical Agitator Control, delivering precise Siemens Programming, and ensuring seamless integration with Nexus DCS. This collaboration demonstrates our versatility in advanced industrial automation.

Key Deliveries

- Agitator logic control and configuration

- Siemens PLC Programming for process precision

- Successful interfacing with Nexus DCS

- Ensured real-time communication and system response

- Enhanced process stability and control reliability

Impact

By streamlining agitator operations and enabling efficient process monitoring, I4Serv has enhanced plant reliability and operational accuracy, supporting consistent product quality.

Quick Resolution of Sinamics 200kW VFD Differential Current Fault for Seamless Production

Project Overview

I4Serv responded swiftly to a critical differential current fault in a Sinamics 200kW VFD and its associated electrical panel at a key production facility. Our expert team ensured uninterrupted operations through precise troubleshooting and immediate rectification.

Key Deliveries

- Identified and resolved differential current issue

- Checked and restored proper VFD functionality

- Prevented potential production downtime

- Ensured electrical panel integrity and safety compliance

- Delivered peace of mind through reliable service

Impact

Our timely intervention minimized operational disruption, preserved production schedules, and reinforced our client’s trust in I4Serv’s dependable field services.

Enhanced SINAMIC Drives with Integrated Troubleshooting via Faceplate Display

Project Overview

To simplify operations and enhance reliability, I4Serv implemented an innovative faceplate feature for SINAMIC Drives. This upgrade displays real-time cause and remedy messages directly on the faceplate, empowering teams to handle troubleshooting and commissioning with speed and precision.

Key Deliveries

- Real-time display of drive faults with detailed cause & remedy

- Seamless commissioning process with quick error resolution

- Enhanced operator visibility and system responsiveness

- Boosted plant uptime through faster diagnostics

- Streamlined maintenance and reduced downtime

Impact

This feature reduces dependency on external tools, cuts down troubleshooting time, and makes commissioning smoother — improving the efficiency of the entire drive system.

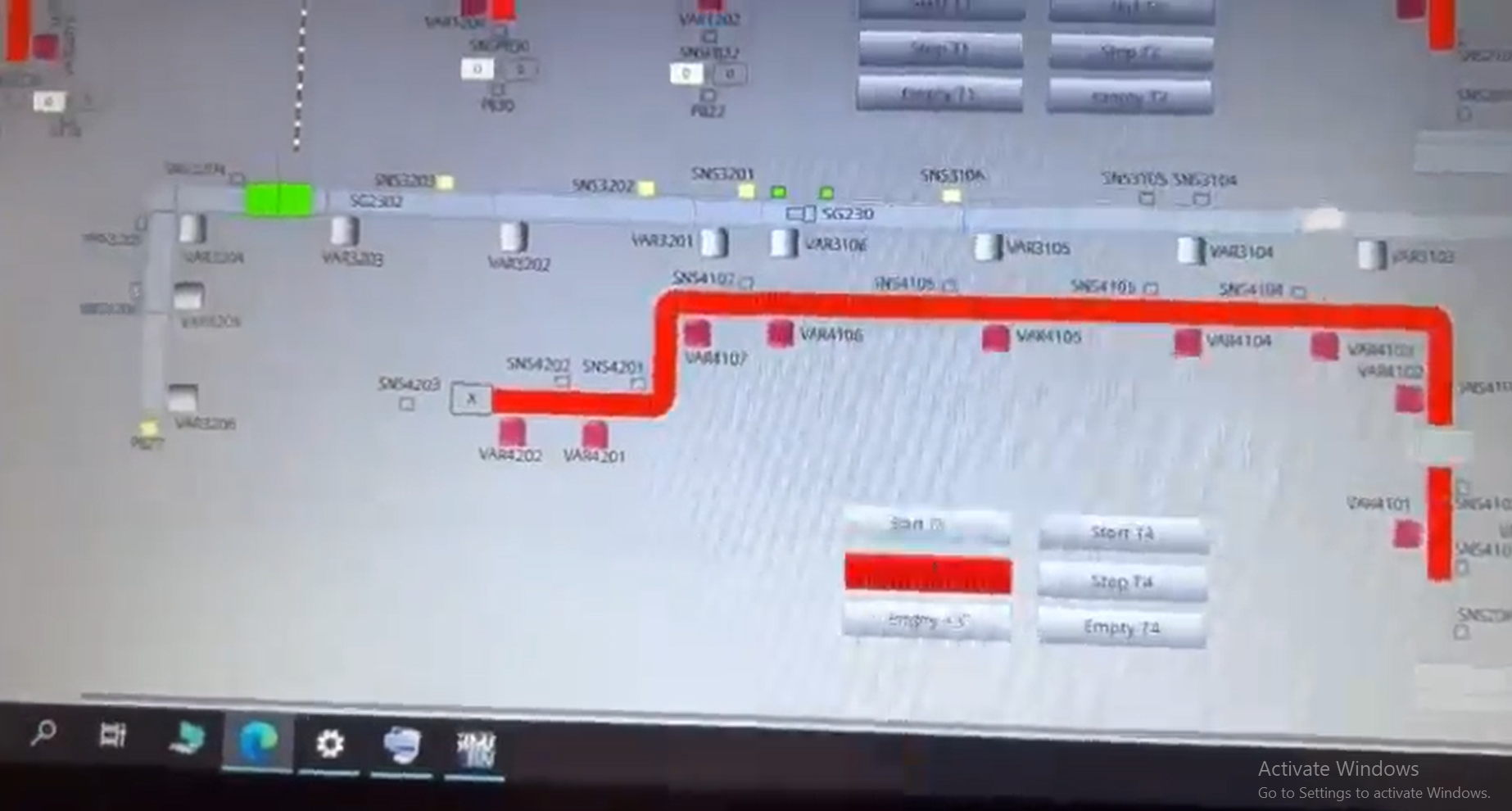

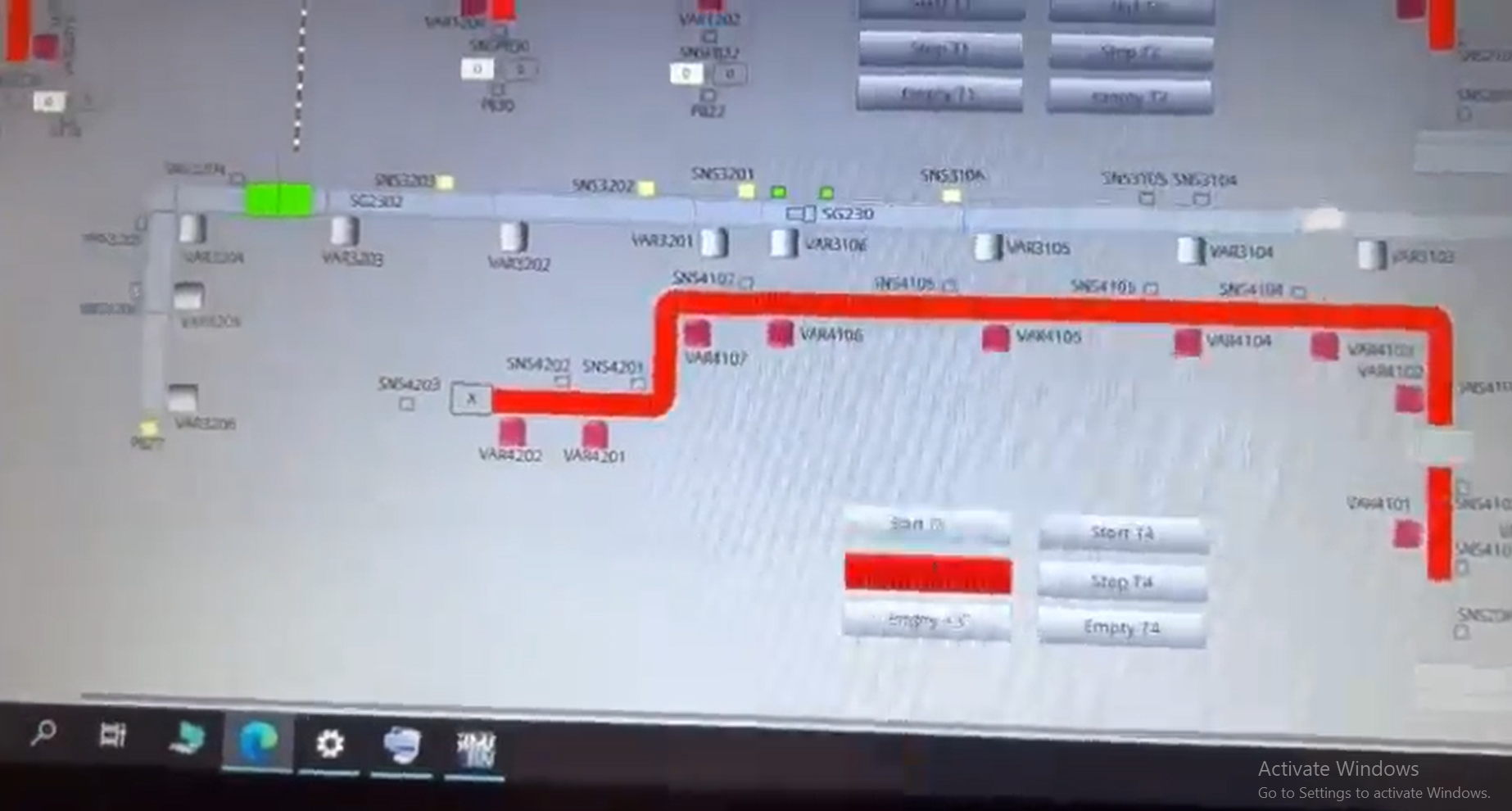

Kickstarting Our First Crates System Line with WinCC Unified + S7-1500

Project Overview

I4Serv has successfully launched the first Line of Crates System powered by Siemens WinCC Unified and S7-1500 PLC. This integration represents a leap forward in our automation capabilities, ensuring smoother, smarter, and more responsive operations.

Key Deliveries

- Full system automation using S7-1500

- Intuitive HMI with WinCC Unified

- Seamless Zoom In / Zoom Out functionality for ease of control

- User-friendly interface to enhance operator efficiency

- Real-time monitoring and data visualization

Impact

The new system reduces operator fatigue, improves response time, and simplifies machine monitoring — setting the standard for future crate system lines.

SCADA Development on TIA Portal for Gas Plant Operations

Project Overview

I4Serv provided specialized automation services for a Gas Plant by designing and implementing a SCADA system using Siemens TIA Portal. This project involved real-time data acquisition using Modbus TCP/IP protocol, ensuring accurate monitoring and efficient control across key plant processes.

Key Deliveries

- SCADA system architecture designed in TIA Portal

- Data acquisition via Modbus TCP/IP

- Real-time monitoring dashboards

- System testing and on-site commissioning

- Device communication configuration and mapping

Impact

The new SCADA system enhances operational transparency, improves decision-making with real-time data insights, and provides a scalable platform for future expansion—contributing to safer and more efficient gas plant operations.

HVAC Integration for Medium Voltage Panels – Cement Plant, Riyadh

Project Overview

I4Serv delivered a reliable HVAC solution tailored for Medium Voltage Panels at a Cement Plant in Riyadh. The system ensures stable thermal management for sensitive electrical equipment, improving overall safety and operational reliability in harsh industrial environments.

Key Deliveries

- Design and deployment of HVAC system for MV panels

- Heat load analysis and system sizing

- Seamless integration with panel enclosures

- Reliable cooling in high-temperature industrial settings

- Enhanced protection for electrical components

Impact

The solution optimized environmental conditions for Medium Voltage equipment, reduced risk of overheating, and extended the operational life of critical electrical infrastructure—helping the client maintain uptime in a demanding cement production environment.

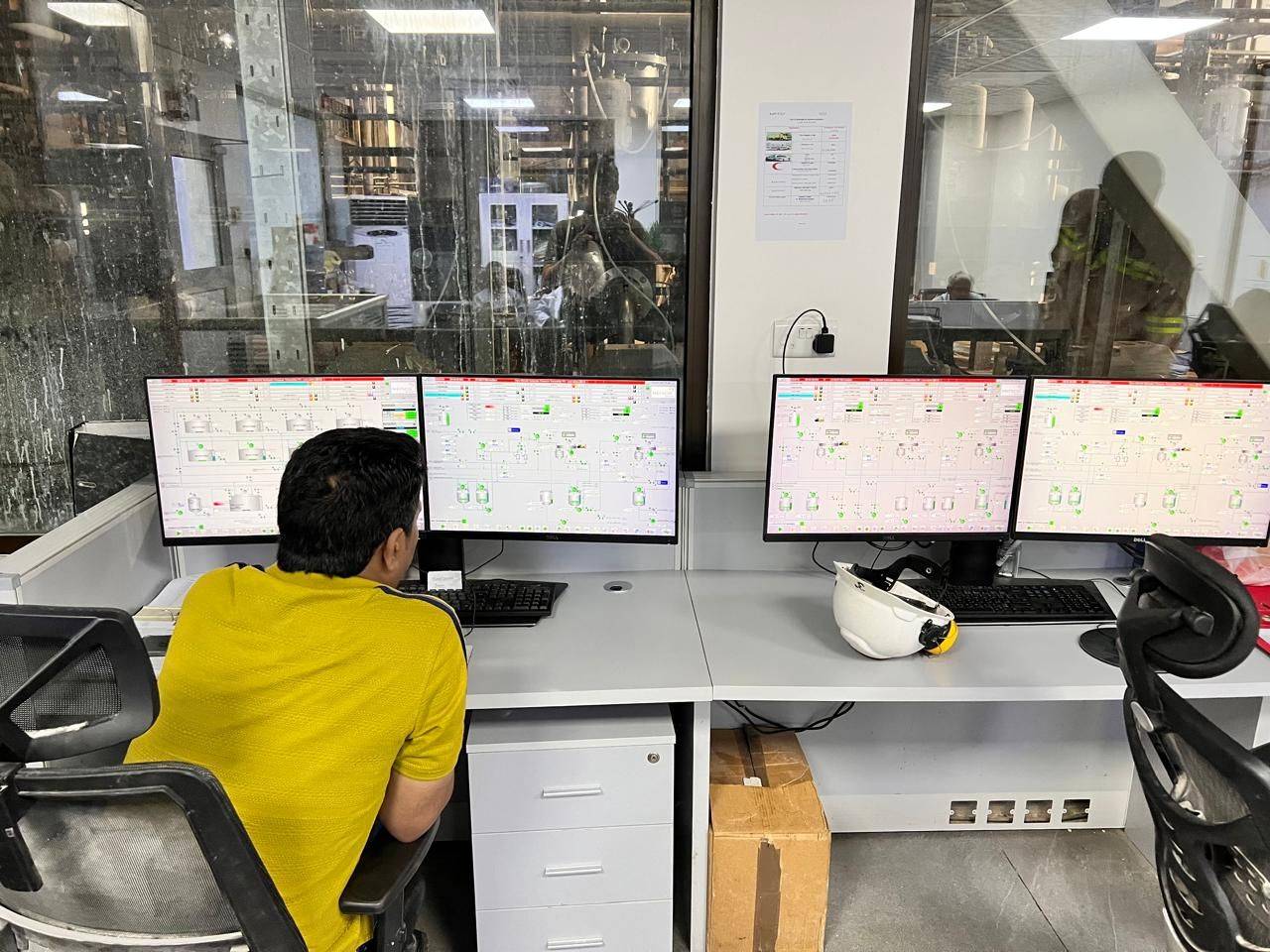

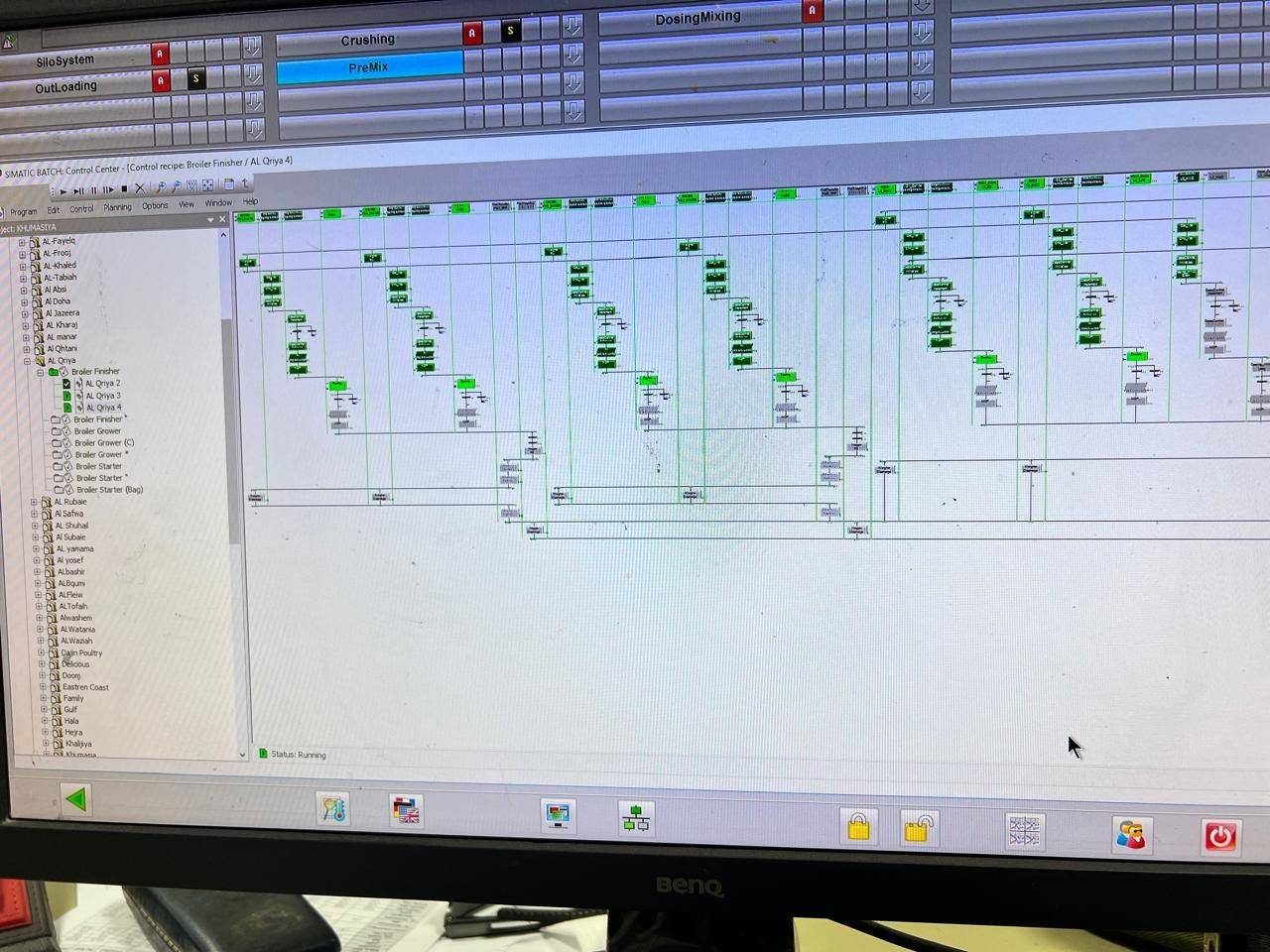

Scalable Flour & Feed Milling Automation with Siemens PCS7

Project Overview

I4Serv successfully upgraded and automated key areas of a major Flour and Feed Milling facility in Dammam. Using Siemens PCS7 Batch 9.1 system, the plant is now equipped with a fully automated control structure ensuring greater efficiency, safety, and operational flexibility.

Key Deliveries

- Full integration of Siemens PCS7 9.1 system

- Real-time automation for milling and co-product areas

- Setup of a centralized control system

- Master recipe and formula configuration

Impact

The upgrade enabled seamless scalability and simplified maintenance, allowing the client to increase production capacity without compromising on consistency or quality. Process bottlenecks were minimized and overall equipment effectiveness was improved.

Upgrade of Gulf’s Largest Starch Plant with Siemens PCS7 9.1

Project Overview

I4Serv successfully executed a major upgrade of the Corn Milling, Co-Product, and Utility Areas at the largest starch processing facility in the Gulf region. The outdated control infrastructure was modernized to Siemens PCS7 version 9.1, enabling enhanced reliability, automation, and scalability.

Key Deliveries

- Transitioned legacy systems to Siemens PCS7 9.1

- Streamlined Corn Milling, Co-Product, and Utility process controls

- Reduced system downtime with advanced automation

- Ensured minimal operational disruption during implementation

Impact

The upgrade resulted in optimized plant performance, improved process control, and better data-driven decision-making. It also positioned the facility for future expansion and compliance with modern industrial automation standards.

FeedMill Process Optimization with Siemens PCS7 – Dammam

Project Overview

I4Serv successfully integrated two Premix Plants at a leading FeedMill in Dammam. The project features a fully automated control system powered by Siemens PCS7 Batch, enabling seamless and intelligent plant operations.

Key Deliveries

- Smart allocation of Batch Units to overcome bottlenecks

- Optimized for process efficiency and accuracy

- Development of Master Recipes and Formulae

- Developed a comprehensive Reporting System for tracking dosing consumption and ensuring quality assurance

Impact

This automation system drastically improved plant performance and enabled data-driven quality control, positioning the FeedMill as a tech-enabled facility in the region.

We Provide the Best Service in Industry

Backed by innovation, expertise, and a commitment to excellence — we deliver solutions that perform and last.